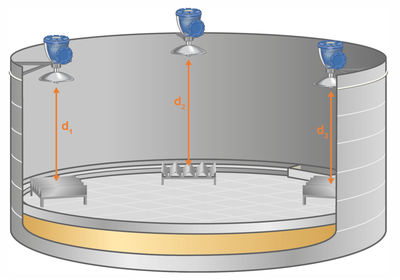

Withdrawal of material from the tank leaving the roof unsupported or the addition of material to the tank forcing fluid up over the roof may cause the collapse of the floating roof.

Floating roof tanks safety.

The floating roof tank animation describes the working principle in the training module.

Floating roof tanks are usually built in a gigantic size and this would involve various disciplines such as civil chemical mechanical fire safety construction inspection commissioning and operation.

For this presentation michael focused on fixed roof tanks.

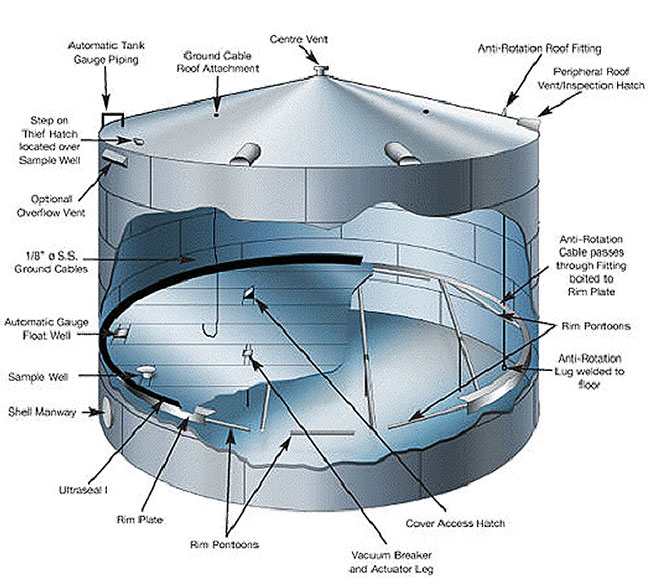

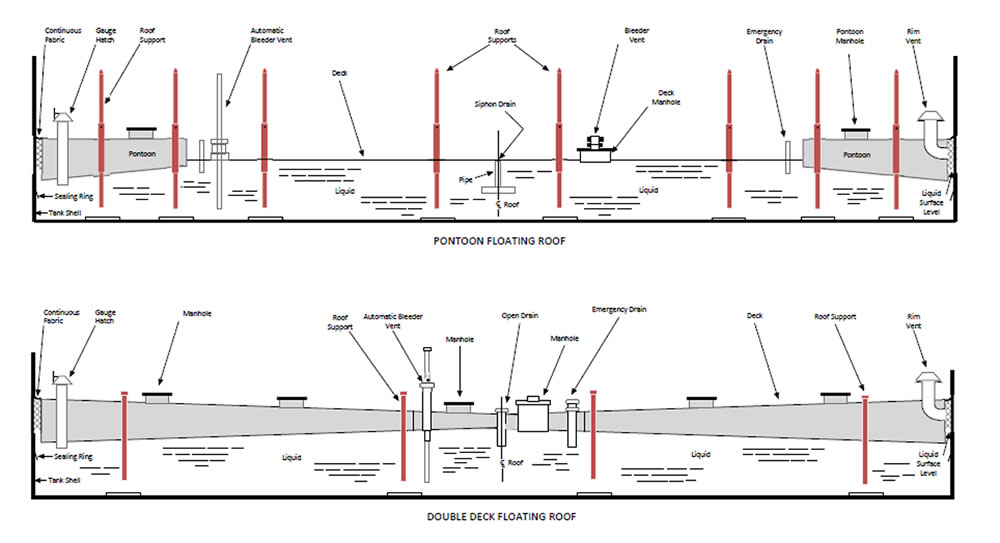

Floating roof tanks may include external floating roof tanks internal floating roof tanks and closed floating roof tanks.

6 steps to achieving external floating roof tank safety.

An additional cause of spills is specific to floating roof tanks.

External floating roofs are fitted atop of large above ground hydrocarbons storage tanks which typically stand in excess of 20m diameter.

This safety notice describes the potential hazards relating to the specification inspection and maintenance of external floating roofs for storage tanks built to bs 2654 1 bs en 14015 2 and api.

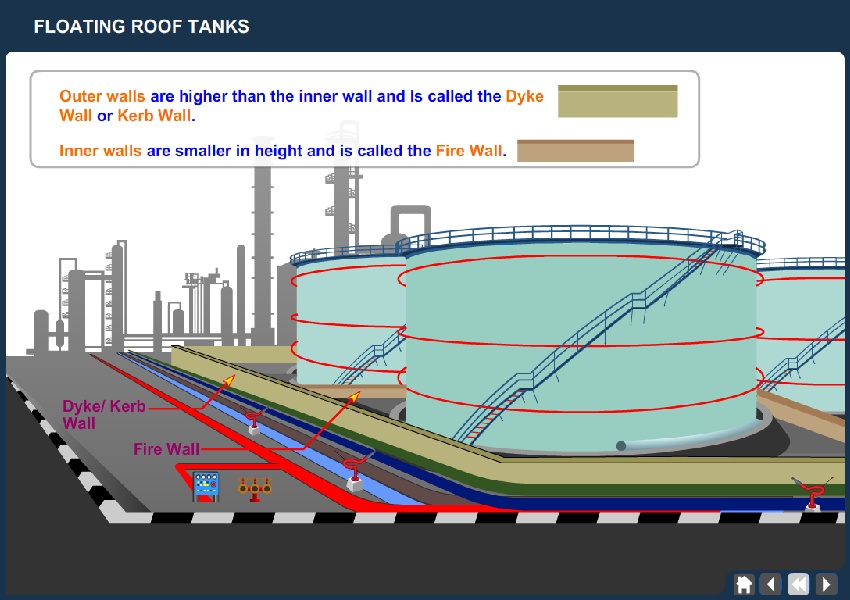

Within refineries and chemical plants many types of storage tanks exist including open top tanks fixed roof tanks and floating roof tanks.

Various aspects of the floating roof tank working like the operation.

The floating roof is smaller than that tank in all directions even when tilted it is hard for it to get hung up especially since you have no columns.

Safety requirements of floating roof tank during operation the floating plate is not allowed to run over the high level also should not be located in the low.

Proper maintenance of external floating roofs for storage tanks is indeed important as failure of the roof can lead to a loss of containment opening the door to the potential of a major accident.

He defined these as ones below 15 psig.

When the floating.

A floating suction or rolling ladder is also unlikely to be strong enough to jam and hold the floatiing roof up.

It is possible for the roof platform to tilt slightly and become wedged into one position.

Moving from open top tanks toward closed floating roof tanks improves safety and product loss controls.

The transport flow of the floating roof tank shall be adapted to the allowable lifting speed of the floating plate.